グリーン スチール用

龍騰の人々は持続可能な開発の本質を深く理解しており、企業開発において常に環境保護と安全生産を第一に考え、積極的に革新を模索し、拡張開発、グリーン開発、調和のとれた開発の道を歩んでいます。龍騰特殊鋼は科学的開発の概念を誠実に実行し、経済建設と環境保護の協調的開発を堅持し、科学技術の進歩と科学的管理に依存し、環境保護ガバナンスをうまく行い、クリーン生産を実施し、生態学的企業を創出し、企業と周辺地域の環境品質を積極的に改善し、従業員の健康を保証し、企業の経済利益、環境利益、社会利益の同期的な向上を実現し、企業の持続可能な開発を促進しています。

Compliance with laws and regulations, improvement of the environment, elimination of pollution, energy conservation and consumption reduction

Longteng Special Steel has invested 5 billion yuan in environmental protection, energy conservation, and ecology, enabling Longteng to achieve high-quality development of the enterprise through green construction。

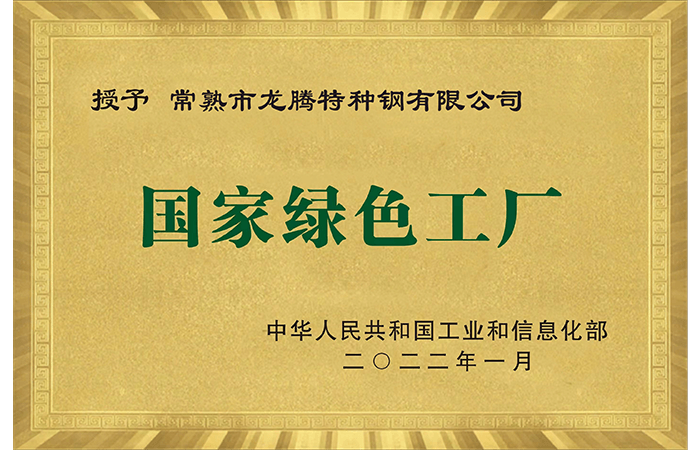

National level green factory

National level green factory

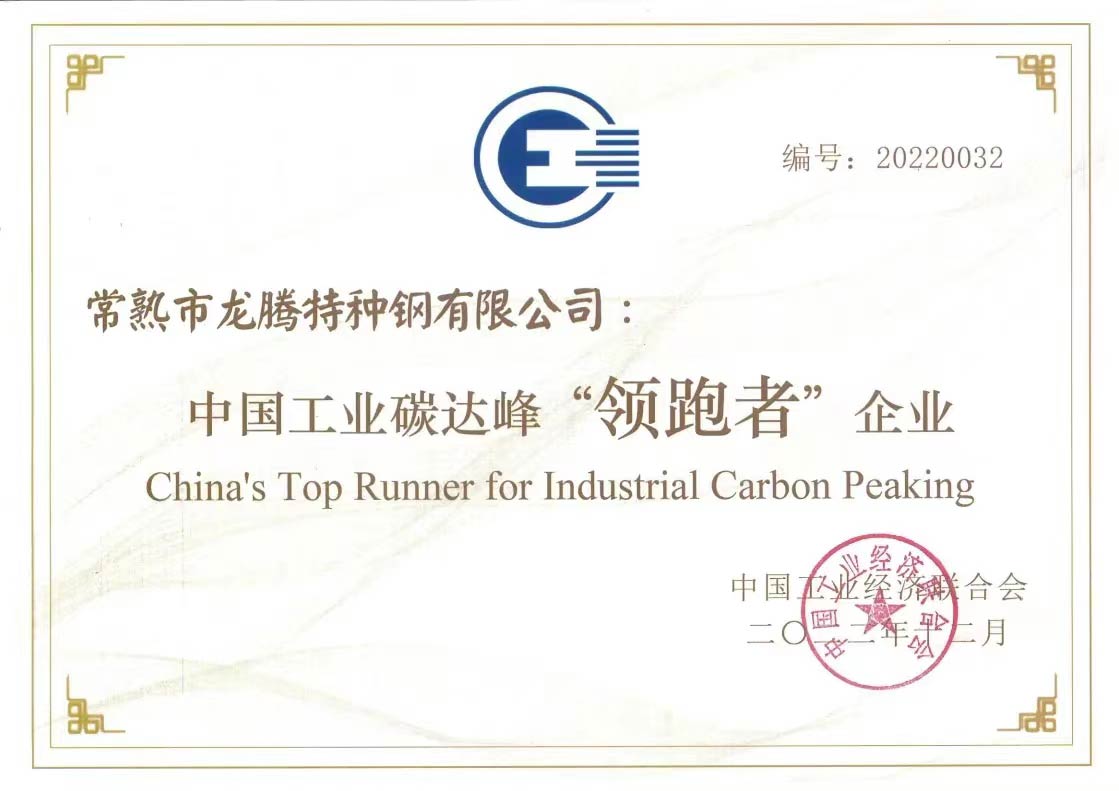

Leading Enterprises in Carbon Peaking

Leading Enterprises in Carbon Peaking

Jiangsu Province Green Factory

Jiangsu Province Green Factory

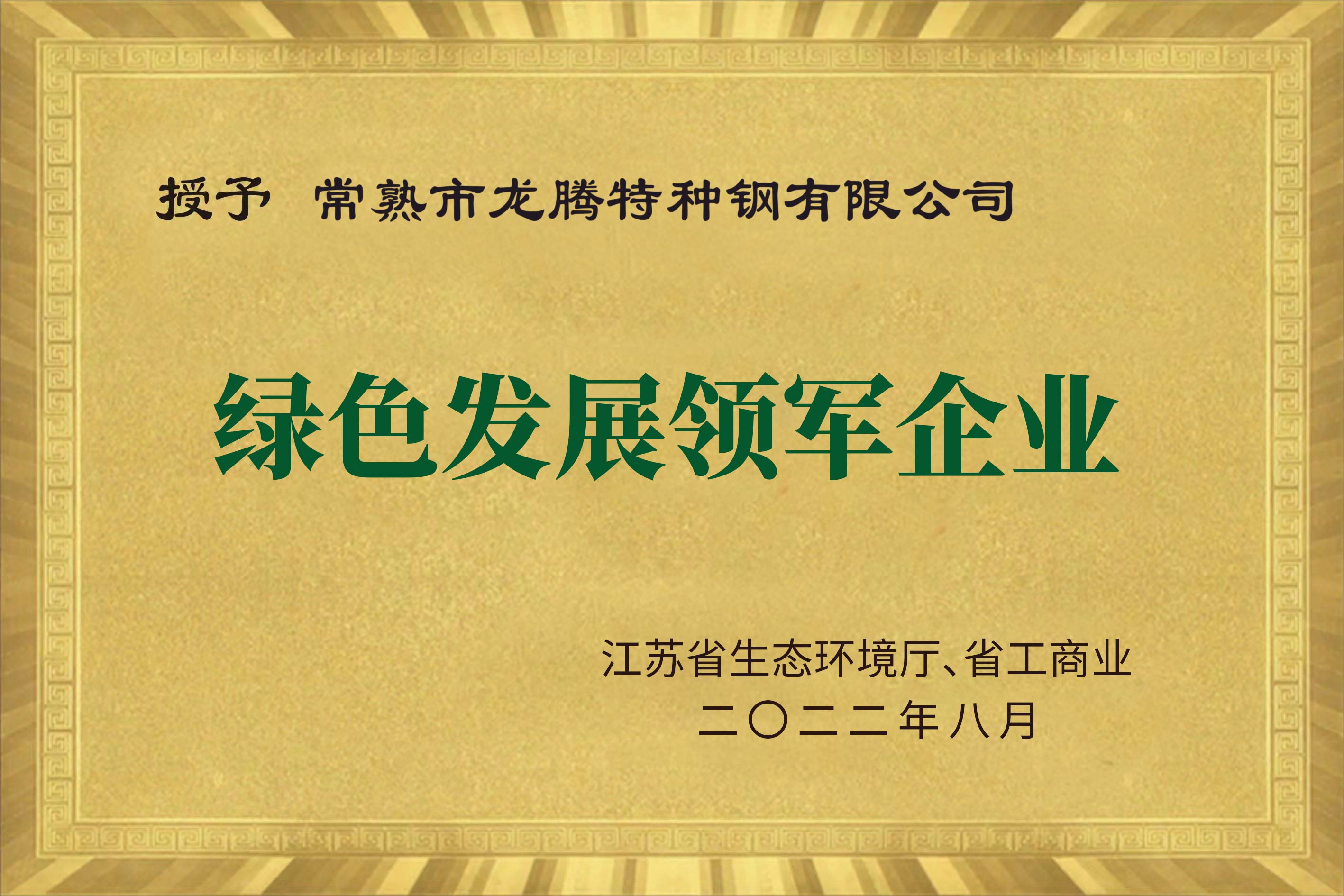

Leading enterprise in green development in Jiangsu Province

Leading enterprise in green development in Jiangsu Province

Ultra low emissions

The company hereby requests the Metallurgical Industry Planning and Research Institute to comprehensively plan and complete the ultra-low emission transformation of the entire steel process for organized and unorganized emissions and clean transportation. The "three wastes" treatment and greening and beautification projects have been fully launched, striving to win the "blue sky defense war" and achieving the goals of "using minerals without seeing minerals, transporting materials without seeing materials, environmental protection ultra-low emission, resource recycling, zero discharge of wastewater, and low energy carbonization". Industrial wastewater has reached a first-class water quality standard after deep treatment, and the "zero discharge" of recycling and reuse has been achieved, achieving harmonious coexistence between humans and nature。

- Particulate matter

2713t/a

Particulate matter2021t/a

25.50%

- Sulfur dioxide

1809t/a

Sulfur dioxide1229t/a

32.06%

- Nitrogen oxide

3100t/a

Nitrogen oxide1340t/a

56.77%

Before ultra-low emission transformation

After ultra-low emission transformation

Energy saving and carbon reduction

Solar energy

Low carbon technology

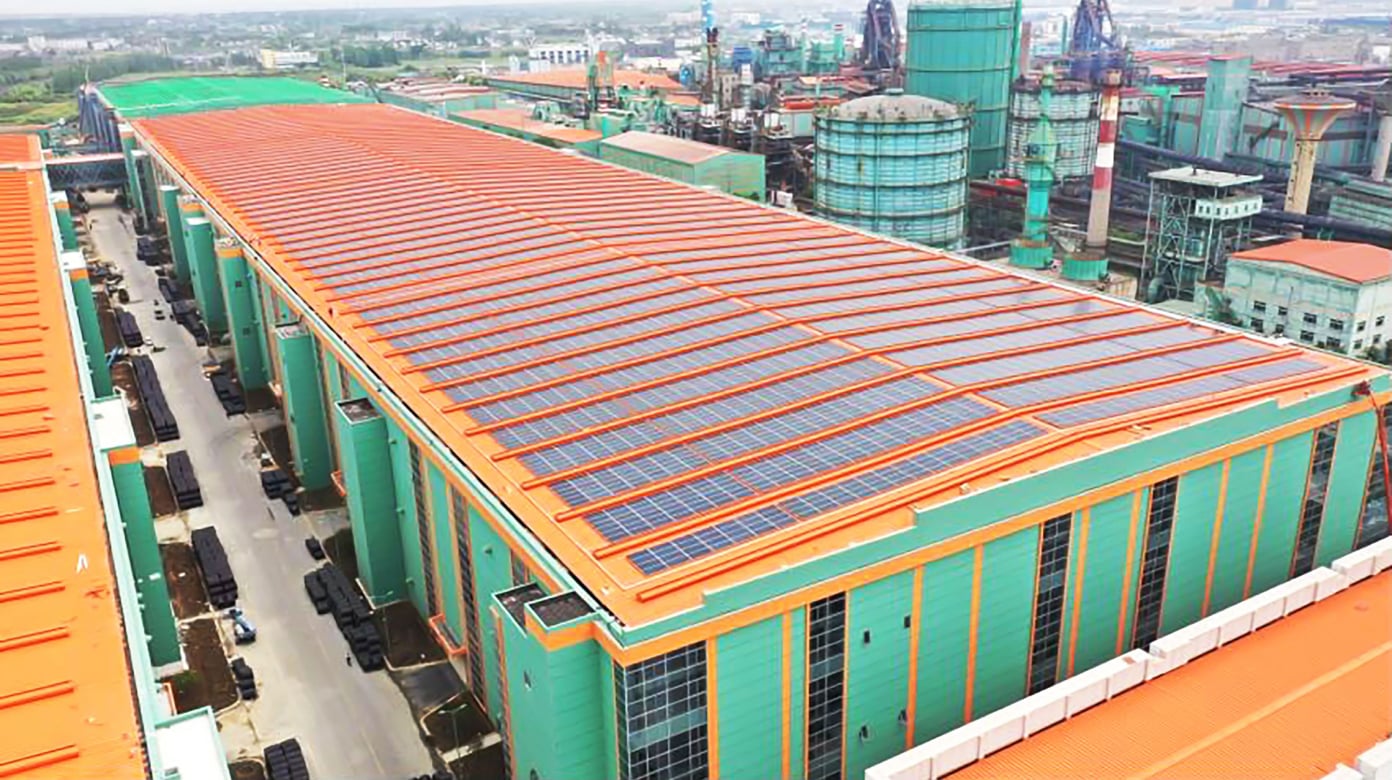

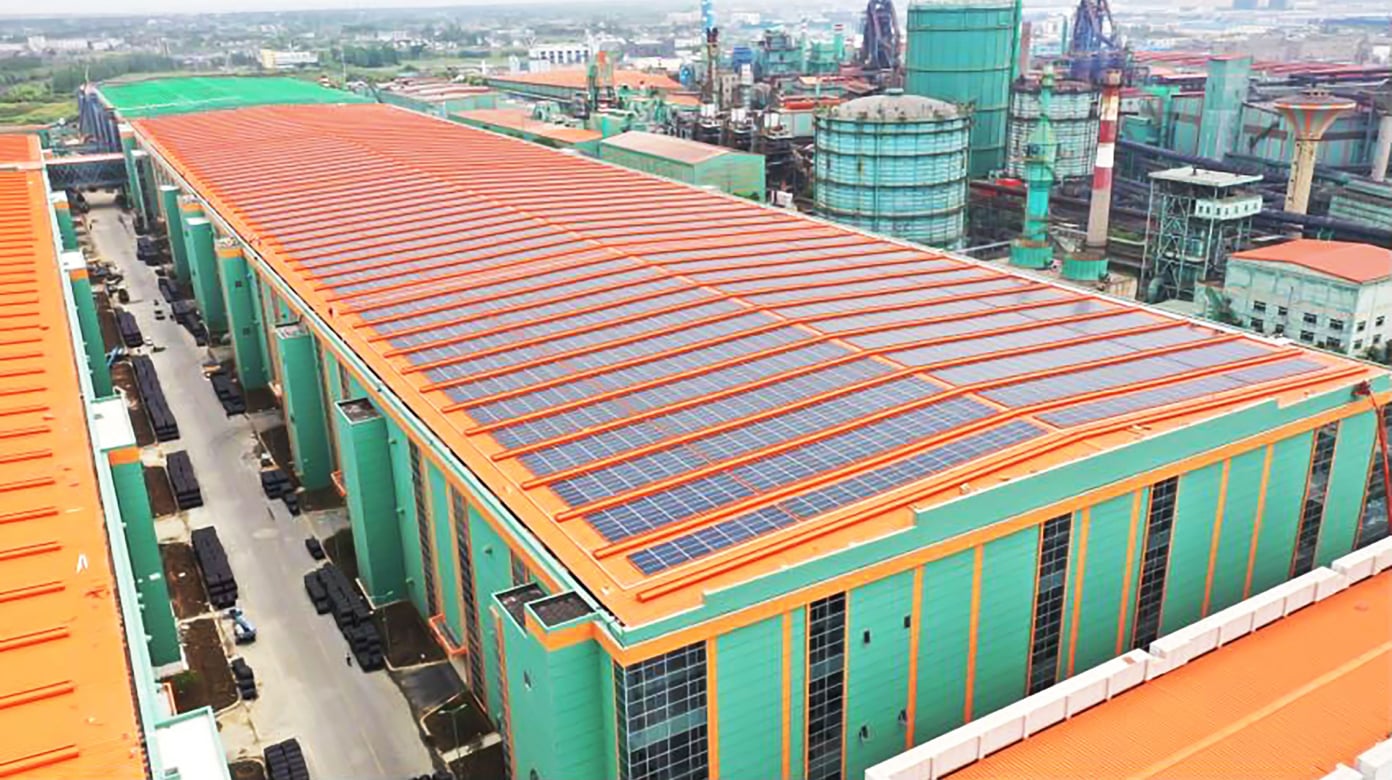

Longteng Special Steel has fully implemented photovoltaic power generation projects and actively utilized the contract energy management model to cooperate with Huaneng. It has completed four phases of photovoltaic power generation projects, greatly utilizing the available roof area of the company, increasing the proportion of renewable energy, achieving a synergistic effect of pollution reduction and carbon reduction for the enterprise, laying a solid foundation for achieving the "dual carbon" goals of the enterprise, and comprehensively enhancing the green competitiveness of the enterprise。

52.89Megawatt

Final assembly machine

5000Over 10000 kilowatt hours

Annual power generation

6000Remaining tons

Annual reduction of standard coal

3000Ton

Nearly annual carbon reduction

Phase II of solar photovoltaic power generation project

Phase II of solar photovoltaic power generation project

Phase II of solar photovoltaic power generation project

Phase II of solar photovoltaic power generation project

Phase II of solar photovoltaic power generation project

Phase II of solar photovoltaic power generation project

Phase II of solar photovoltaic power generation project

Phase II of solar photovoltaic power generation project

Phase II of solar photovoltaic power generation project

Phase II of solar photovoltaic power generation project

Phase II of solar photovoltaic power generation project

Phase II of solar photovoltaic power generation project

Multiple national key energy-saving and low-carbon technologies and industry advanced technologies have been applied, including blast furnace dehumidification, ring cooler liquid sealing, thick material layer sintering technology, regenerative combustion in heating furnaces, enhanced radiation energy-saving technology in heating furnaces, variable frequency energy efficiency system for belt conveyors, and energy control in the steel industry, to improve energy efficiency and reduce greenhouse gas emissions。

Blast furnace dehumidification

Blast furnace dehumidification

Enhanced radiation energy-saving technology for heating furnaces

Enhanced radiation energy-saving technology for heating furnaces

Smart Energy Conservation

Smart Energy Conservation

循環型経済

-

残留ガス発電

同社は自社の余剰ガスを利用してガス発電を建設し、50MWの高温超高圧発電ユニットと世界初の60MWの超高温亜臨界発電ユニットを相次いで建設しました。同社は国の二重炭素政策を満たすと同時に、省エネ、コスト削減、効率向上も推進し、企業の利益を増やし、生産を確保しています。

-

廃熱発電

焼結廃熱回収は、焼結工程におけるエネルギー消費を削減し、エネルギー利用効率を向上させる重要な方法です。基本原理は、リングクーラーに空気を吹き付けて焼結鉱を冷却し、底部から吹き込まれた冷気は高温の焼結鉱層を通過する際に加熱され、高温の排ガスになります。また、焼結機の一部では、底部から煙道に高温の排ガスを引き込み、誘引通風機を通してボイラーに導入し、ボイラー内の水を加熱して蒸気を発生させることで、焼結鉱を製造します。蒸気はタービンを回転させ、発電機を駆動して発電します。

Ecology Factory

Fully implement ultra-low emissions and strive to build a garden factory。

Entrusted with the professional design of Nanjing Forestry University, with an investment of 150 million yuan, to build a 427 acre Longteng Ecological Picking Garden, surrounded by orchards, forests, and green shade. It integrates the "Party Building Center", "Reception Center", and "Employee Activity Center", expanding the green area of the factory to 41.3%。

1.5hundred million

Green construction investment

427Mu

Longteng Ecological Park

41.3%

Factory green area

Email

Email